Toby Fehily

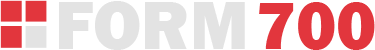

Robert Hague’s Stride Orbis, a concrete sculpture commissioned for the new headquarters of Australian construction company Form 700, says as much about the construction company as it does about construction itself.

The 65 tonne, 5.1 metre-tall monument, with its complex, interwoven compound curves, even seems to speak to the very artistry of construction. And were it not for help of some of the brightest minds in structural concreting, it is doubtful this ambitious sculpture would have ever been realised.

“We had people doubting it would be possible to make such a shape,” says Hague. “It’s just not something you see in concrete”.

The idea for the sculpture had been forming in Hague’s mind for some time, namely how the repeating simple shapes can result in complex configurations. Straight away, Hague saw parallels with Form 700 and the construction industry at large, whose job is to harness raw, simple materials to make complex structures.

The sculpture’s fluted hexagonal base, inspired by Roman columns, is intended as a reference to the company’s Italian heritage. And the sculpture itself, with its looping, twisting arches, recalls Mobius strips and infinity symbols – a tribute to Form700’s long and continued success.

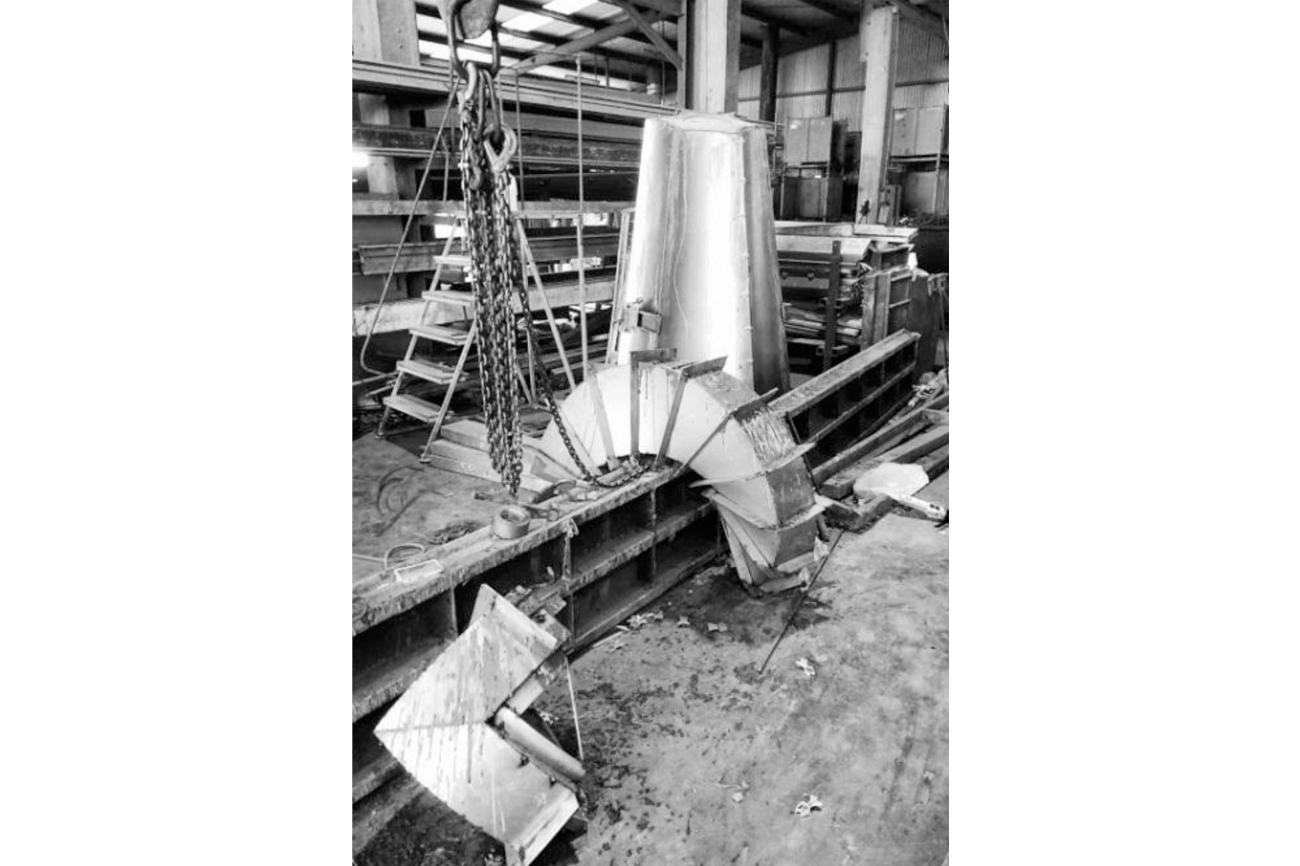

After presenting a stainless steel scale model, Hague got Form 700’s approval, and started planning for the concrete. Hague had never worked with the material before. For the previous 20 years, the New Zealand-born, Melbourne-based sculptor had worked almost exclusively with stainless steel and bronze.

Form 700, Dinale Precast and the artist formed a project team.

“It was a learning curve for all sides,” says Hague. “We saw the opportunity to utilise our strengths – theirs in construction and pre-casting and mine in metalwork.”

“Concrete and steel is the perfect marriage”.

From his studio workshop, Hague fabricated the steel moulds that form the repeating curve and corner sections. Inside these, hydraulically formed stainless steel plates act as connectors and as the backbone to the steel reinforcing system – a pattern of welded flat bar and rods.

Form 700 called on Hy-Tec Concrete to design a concrete mix that could meet the sculpture’s structural demands. The main worry, the engineers said, was the flex – “the work is a bag of springs,” they warned. To get around this, they created a tailored 80 mpa polymer fibre reinforced concrete mix strong enough to withstand the inherent forces.

Today, the sculpture looms outside the new Form 700 headquarters in Altona. Thanks to a flash of inspiration at the eleventh hour, it’s markedly different from the building’s gleaming black glass and red detailing – even from the polished stainless steel working model of the sculpture that now stands in the lobby.

Late in the design process, Hague had secretly made a small mould and cast a test piece in raw, plain concrete, not stainless steel. It was a disaster, structurally weak and full of air-pockets but it hinted at how these helical curves could be formed and, more importantly, how the muted tones of concrete grey might triumph.

Looking at Stride Orbis today, you can appreciate the importance of this late change. Just the sculpture alone, regardless of its final finish, seems to challenge our ideas about what construction can be, with its interwoven, arching shapes suggesting a fluidity that belies its solid state. But the raw concrete finish, together with the exposed bolts and joints, leaves the sculpture’s cards on the table.

The daring artistic vision about what construction can achieve doesn’t conceal the construction that went into it, but rather gives it credit, almost shows it off as an act of artistic creation in itself. Like the curves themselves, the ideas about art and construction in Stride Orbis seem to loop around each other.

Hague, the metal sculptor, admits he was surprised to find himself so taken with the concrete. He intends to continue working with it. When asked why, he gestures to the arched, twisting curves of grey concrete and shrugs. “Concrete is beautiful,” he says.

Footnotes:

Client – Emilio Rosati, Form700 head offices Melbourne – www.form700.com.au

Artist – Robert Hague – www.roberthague.com

Location – 68-76 Drake Boulevard, Altona, Victoria 3018, Australia

Material – 304 stainless reinforcing structure with high strength polymer fibre concrete.

Partners – Form700, Dinale Precast, Hy-Tec concrete, AASM, Di Metal Design and Sergi cranes.

Total weight – 65,000kg (including 40t footing).

Standing height – 510cm.